There are Two Main Types of Fall Protection Systems

But which type of fall protection system is better, the Fall Restraint or Fall Arrest System? Fall protection systems may seem complex and difficult to understand, but when you break down the terminology, you gain a better understanding of how fall protection systems work, why fall protection is needed, and which system needs to be installed for your specific situation. You see, it’s not really a question of which is better, but which is better for your application.

Two terms used in the field that seem almost identical are “Fall Arrest” and “Fall Restraint”. Although the words may seem similar, they have very important differences that you need to be aware of.

Type 1: Fall Arrest System

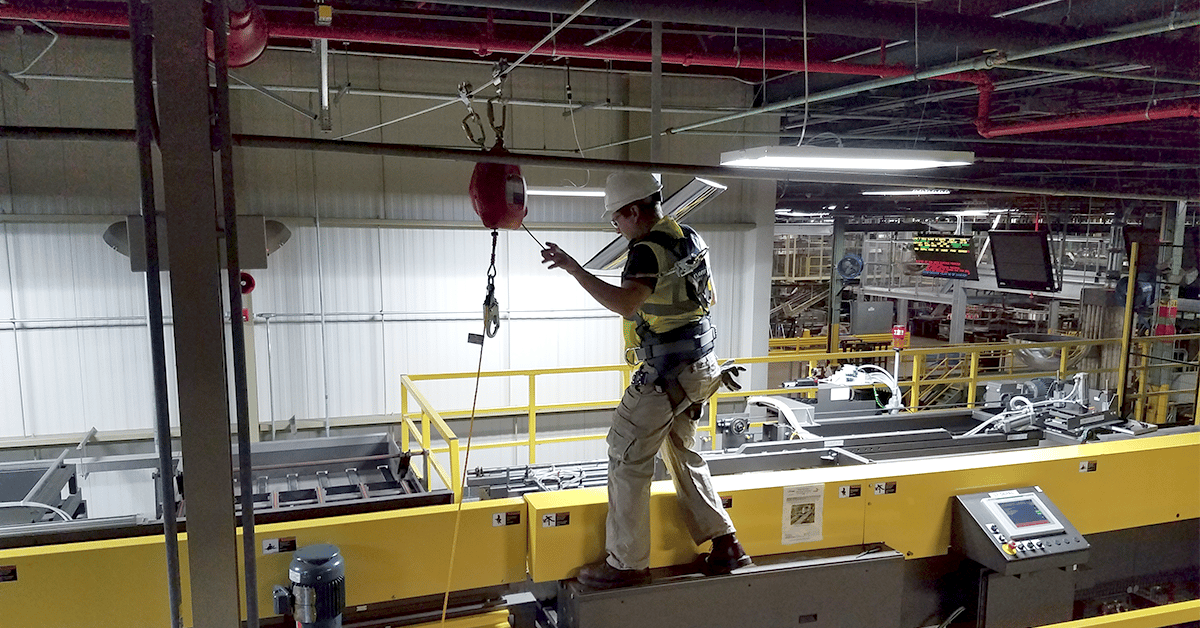

Fall Arrest means protecting a worker that has already fallen. The worker reached a leading edge, their center of gravity broke the leading edge and now their fall needs to be stopped before they reach the lower level.

With the help of safety harnesses, anchor points, and energy absorbers such as: shock pads, rip stitch lanyards and disk break mechanisms, a worker’s kinetic energy can be absorbed by the fall arrest system rather than the worker’s body. With that in mind, it’s important that the worker wears their harness properly, and attaches themself to the appropriate anchor points, to make sure the fall arrest system successfully does what it was designed to do.

Fall arrest systems are ideal for places with potentially dangerous locations that need to be accessed frequently. They allow workers to safely work in and around these seemingly hard to reach places. A fall arrest system is also required in work environments with slopes greater than 18.4 degrees. The slope itself becomes the fall hazard and the worker needs to be safely protected against the leading edge.

The downside to a fall arrest systems is its increased need of individuality, meaning each system is custom made to fit the needs of the work environment and also the needs of the workers using it. Fall arrest systems also require thorough training on how to properly use the system. Although training may take time and money, workers gain a better understanding of how the system works and become better prepared to deal with fall hazards.

Type 2: Fall Restraint System

Fall Restraint means the worker is restrained from reaching a fall hazard. This restraint can be provided by a fixed-length lanyard, a body harness, a body belt and in some cases, a simple guardrail. Because these restraints are easy to install and don’t require workers to go through training, fall restraint is the most preferable method of fall protection.

Under the umbrella of fall restraint falls two more terms, “passive fall protection” and “active fall protection”.

Passive Fall Protection

Passive fall protection means workers are protected from a fall by something as simple as a guardrail on a balcony or a handrail on a staircase. No training is needed on how to use equipment in passive fall protection systems.

Active Fall Protection

Active fall protection is a little more complex because it involves the workers having to take necessary steps to ensure they maintain their safety. This involves short-length lifelines and workers need to be trained on how to properly use the equipment in an active fall protection system.

Fall restraint systems are beneficial for working surfaces with slopes between 0 degrees and 18.4 degrees*. They provide simple safety for workers in dangerous environments and prevent them from reaching fall hazards. With that being said, fall restraint systems such as guardrails and netting can make it difficult to reach different locations on a worksite. They do not provide the free mobility that a fall arrest system provides, which means workers can’t easily access hard to reach places.

Our Certified Fall Protection Experts are here to provide you with the support you need for your next fall protection system, from take-off and design through installation. Get started today with a free quote from our Fall Protection Experts!

*The 18.4 degree mark is used because a common roof has a 3/12 pitch. ANSI Standard Z359.3 – Subsection 3.2.2 also uses the 18.4 degree mark to distinguish between the need for a fall arrest system or a fall restraint system. Although ANSI standards are not legally recognized like OSHA standards, they are still accepted internationally and can be referenced by OSHA under the general duty clause.