How Often Should You Inspect Fall Protection Equipment

According to the Occupational Safety and Health Administration, “Personal fall arrest systems shall be inspected prior to each use for wear, damage and other deterioration, and defective components shall be removed from service.” This means all connection points, fall protection harnesses, lanyards and lifelines should be checked before performing any work that may result in a fall related injury or accident.

How Often Do Fall Protection Harnesses Need To Be Inspected

Similar to the fall protection equipment, OSHA states that, “Personal fall protection systems must be inspected before initial use during each workshift for mildew, wear, damage, and other deterioration, and defective components must be removed from service. Ropes, belts, lanyards, and harnesses used for personal fall protection must be compatible with all connectors used.”

OSHA Fall Protection Inspection Requirements

Keeping employees safe and preventing workplace accidents should be priority #1. To make sure you’re able to achieve maximum safety, OSHA provides a Fall Protection Plan that provides you with the requirements and standards for the equipment, systems, lifelines, lanyards and harnesses needed to be in compliance. This will ensure your workers are protected from slips and falls.

ANSI / ASSP Fall Protection Equipment Inspection Requirements

Along with OSHA, The American National Standards Institute (ANSI) and The American Society of Safety Professionals (ASSP) have fall protection requirements when it comes to installing and inspecting harnesses and fall protection systems. These standards address hazards relating to falls through roof openings, falls to lower levels and other hazardous work zone situations. Known as the ANSI/ASSP Z359 Fall Protection Code, our Fall Protection experts make sure all installed equipment meets the code and your workers will stay safe in the event of a work place accident.

A Fall Protection Plan Should Include Which Of The Following?

- Identifying Fall Hazards

- Passive Fall Restraints

- Active Fall Restraints

- Fall Arrest Systems

- Rescue Equipment & Emergency Plans

The answer is all of the above. Fall Protection Plans are designed with safety in mind to keep workers safe from work place accidents. Having all of the above, if applicable, is crucial to saving lives.

What Are The Top Fall Protection Plan Priorities?

Identifying Fall Hazards

One of the first steps of a fall protection inspection is identifying the potential fall hazards. This may include rooftop obstacles such as pipes, electrical trays, HVAC units, roof hatches and unprotected roof rail edges. Once theses hazards are identified, an inspection of the fall protection equipment and harnesses begins. This also Includes an evaluation of additional equipment that may need to be installed in order for the workplace to be in compliance with OSHA standards.

Passive Fall Restraints

Passive fall restraints refer to a fall protection system that is installed when there is the chance a worker may fall over the edge of a roof, into a roof hatch / sky window or off a catwalk. Our fall protection inspectors will quote guardrail systems to counter this issue. Our guardrail system is OSHA approved and will prevent workers from encountering the danger of having this type of accident.

Active Fall Restraints

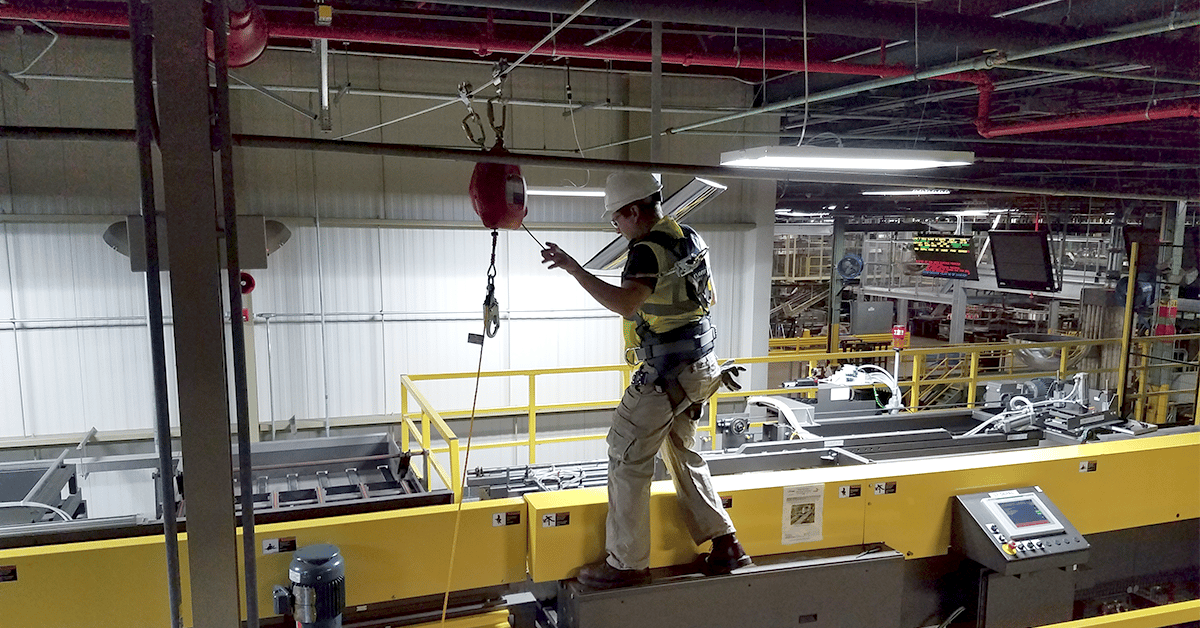

A Fall Protection Harness, or Active Fall Restraint, is a personal safety device that workers use to prevent fall related injuries. This personal body harness, along with the proper lanyards, lifelines, connectors and wiring system, allow the worker to maneuver around hazardous situations while remaining safe and OSHA compliant.

According to OSHA guidelines, “a fall restraint system must have the capacity to withstand at least 3,000 pounds or twice the maximum expected force that is needed to restrain the person from exposure to the fall hazard.”

Fall Arrest Systems

Like the Active Fall Restraint systems, a Fall Arrest System consists of a body harness, lifelines, connectors, an anchorage system and a personal fall arrest system that allows a falling worker to safely stop (arrest) before injury may occur. When used in conjunction with an active fall restraint system, maximum safety can be obtained.

Rescue Equipment and Emergency Plans

As much as we hope that it never comes to this point, having rescue equipment and an emergency plan can make a difference between life and death. Making sure you have the necessary rescue equipment (fire extinguishers, ladders, scaffolding / etc.) to recover or get to a fallen worker is crucial. Having an emergency plan will also aid in preventing a terrible workplace accident.

Who Is Fall Protected Solutions?

Fall Protected Solutions (FPS) is a division of Strut Systems Installation LLC (an Eberl Company). We work with you to provide custom fall protection systems that keep your employees and maintenance workers safe. Our services include:

- Fall Hazard Assessment

- Fall Protection Plan Creation

- Fall Protection Inspection

- Project Planning

- Project Management

- Take Off & Design

- Design Engineering

- Installation

We also specialize in roof walkways, catwalk construction, access platforms and fall protection harness systems. We also offer Fall Protection Inspections, making sure your safety systems are OSHA compliant.